From the Tredyffrin Easttown Historical Society / History Quarterly Digital Archives / Winter 2006 Volume 43 Number 1

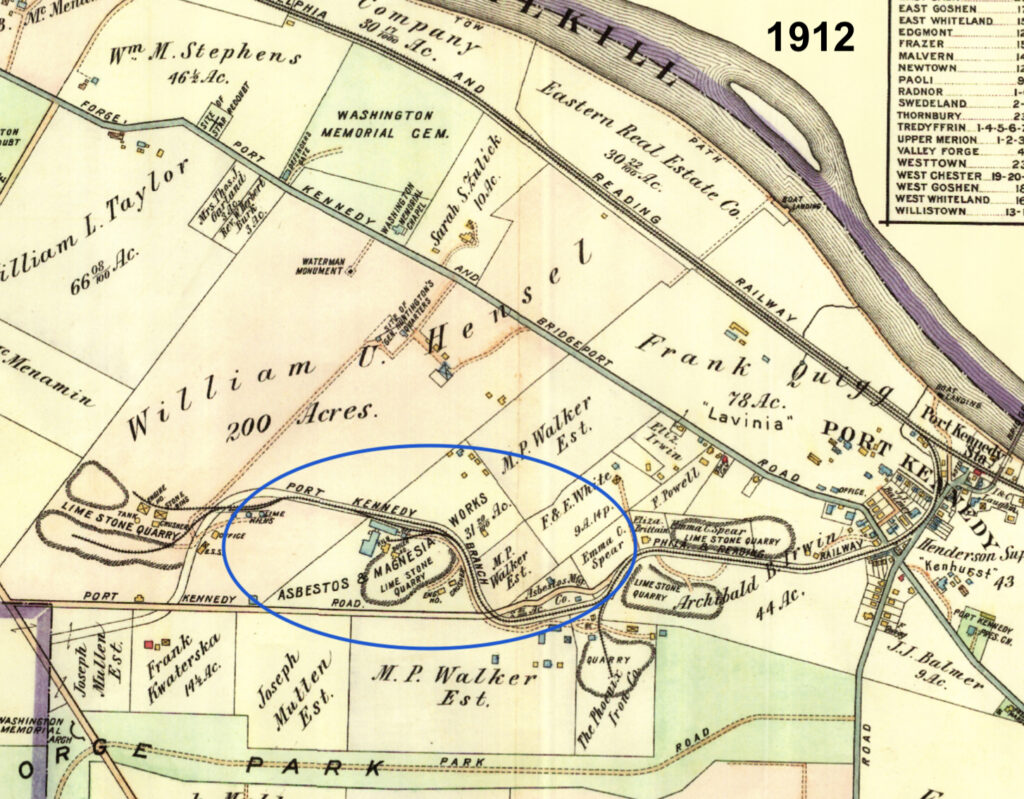

The manufacture of magnesia products was another use for the dolomitic limestone of the Great Valley. This is calcium magnesium carbonate, not the calcium carbonate of normal limestone. Between … 1877 and the construction of their first buildings in 1895, the Ehret Magnesia Manufacturing Company started buying up and consolidating many of the smaller Port Kennedy quarries. … the magnesium content—carbonate of magnesia—of Port Kennedy limestone was as high as 42% (vol. 1, p. 26)—very high.

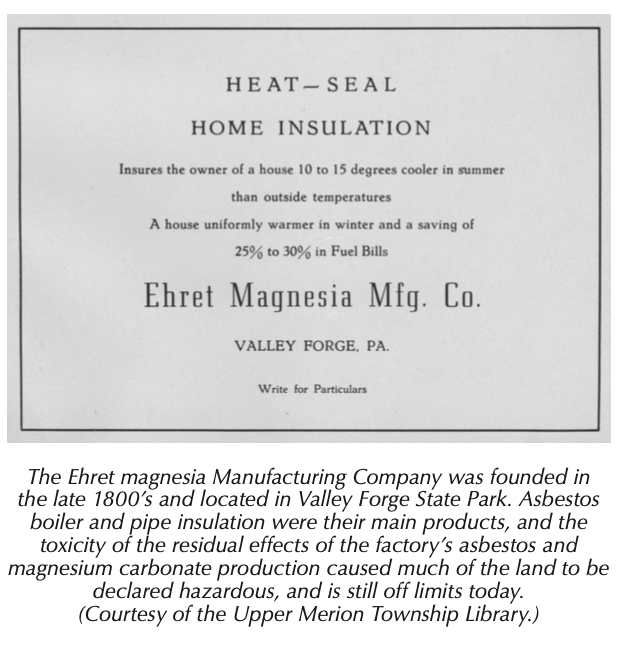

Asbestos is a naturally occurring mineral silicate with strong white fibers. The insulating and flame retardant qualities of asbestos were known as far back as ancient Rome and by the Industrial Revolution at the end of the 1800s, asbestos was used in the manufacture of thousands of products. By the 1970s the health hazards of asbestos had become known.

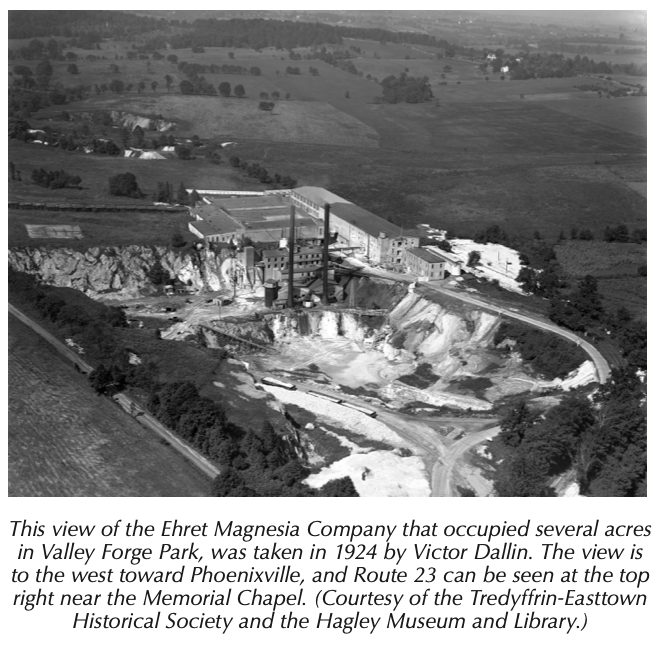

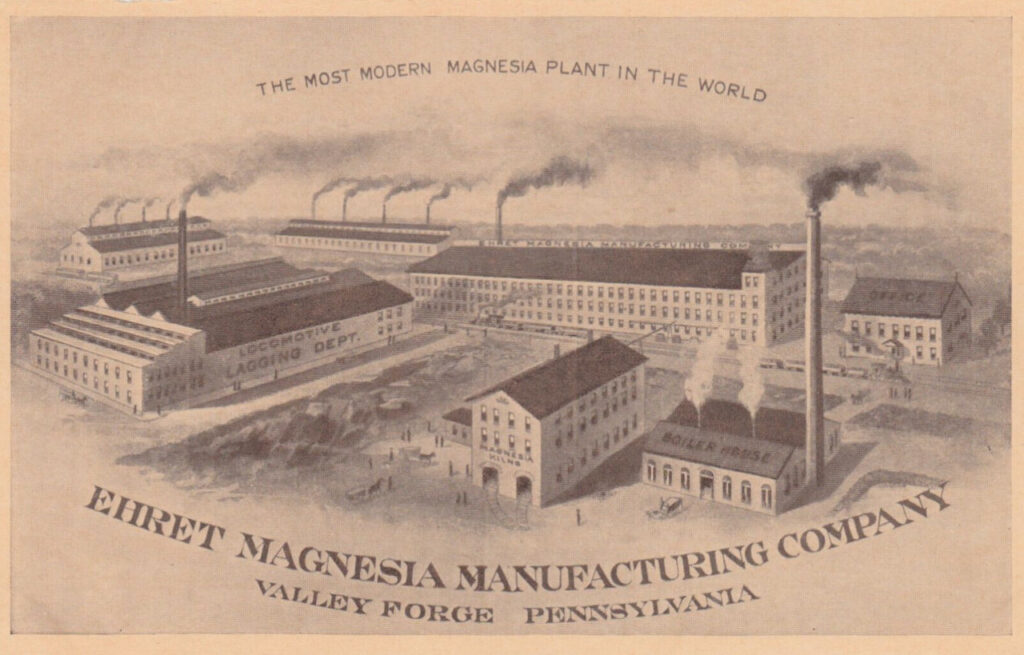

This was what Ehret was manufacturing in Valley Forge. They specialized in what were called 85% magnesia products—insulating pipe covers, insulating blocks, and felt fiber. The 85% was the magnesia; the other 15% was the mineral silicates—the stuff that causes asbestosis and mesothelioma. Over the course of its 80-year history in Valley Forge, Ehret built 20 buildings.

… During World War I Ehret was manufacturing insulation products the U.S. Navy needed at the same time the park was planning to acquire—by demolition—land on which plant workers’ houses stood. The commission delayed its plans in support of the war effort. After the war, Ehret planned to spend $100,000 to build new workers’ housing and make other improvements to its plant site next to the park. Ehret refused to cooperate when the park commission resumed its demolition of workers’ houses and the commission retaliated by declaring Ehret’s new proposed housing tract a future part of the park…

… As the company grew, its name was changed to the Baldwin-Hill Company, in 1959 to Baldwin-Ehret-Hill, Inc., and some time in the 1960s or early 1970s it was purchased by the Keene Corporation, a Fortune 500 company. By that time the plant was completely surrounded by land owned by the park. Keene continued manufacturing insulating pipe covers and blocks, felt products, and insulating cement. Between 1925 and the early 1970s Ehret and its successors disposed of waste products from manufacturing operations directly into the Schuylkill River and through a slurry pipeline into several of the inactive limestone quarries.

… in 1975 the U.S. Department of the Interior recommended that the Keene property be purchased and gave an estimated cost of $3,878,450 (p. 559). The plant was closed in 1976 and the rail spur was abandoned. On October 13, 1976 the National Park Service purchased the 46-acre Keene property and the asbestos manufacturing plant. The site had been heavily vandalized and the park razed several of the buildings in 1978.

… In January 1997, while installing underground fiberoptic cable in the amphitheater area, the park discovered asbestos in the soil. The U.S. Environmental Protection Agency was brought in and between May and October of 1997 emergency response action was taken to abate immediate risks to public health and the environment in all quarry and related areas. All quarry buildings and structures were demolished and buried and, since these areas were popular with hikers and rock climbers, all access was restricted.

Today it is nearly impossible to determine the location of the Ehret/Keene site. If you drive along County Line Road to the point where you can look north across the rolling hills and see the Washington Memorial Chapel bell tower in the distance, the land just to your left in front of you is where it was.